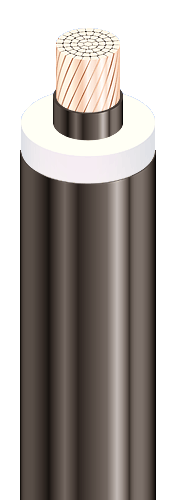

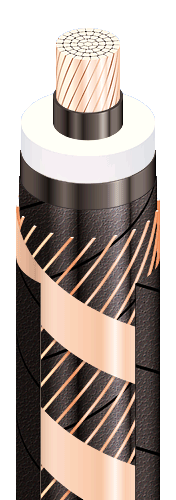

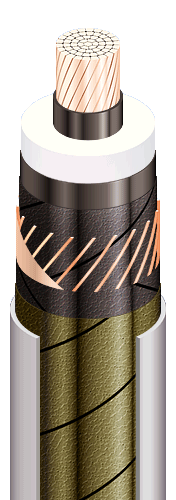

ÏâÅÑÏó-132 1x800

ÒÓ Ó 31.3-00214534-060:2011 |

| Power cables with copper conductor, XLPE-insulated, with copper screen, lead-sheathed, with reinforced outer sheath of polyethylene |

| Technical cable requirements correspond to IEC 60840 |

|

|

|

| Cables are used for laying: |

| • in places, where small mechanical impacts on cable are possible, including tensile forces |

| • in soil (trenches) with high corrosiveness |

| • in damp, partially flooded premises |

| • in wetlands |

| • in non-navigable waters |

| • on difficult route sections, according to the unique specification |

| • in the air, including cable structures, if provided the additional fire protection |

|

|

|

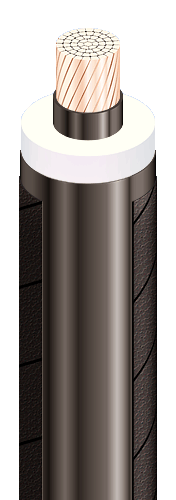

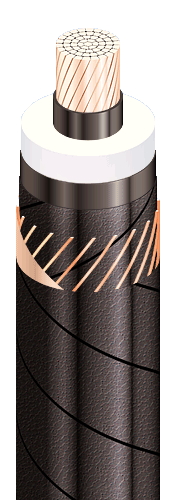

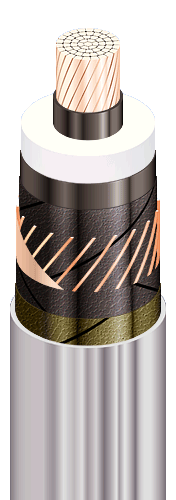

It is possible to manufacture cables with extruded semiconductor layer along outer sheath.

Order entry example: |

| ÏâÅÑÏó-Ï–132 1x800/95 ÒÓ Ó 31.3-00214534-060:2011 |

| An extruded semiconductor layer along outer sheath ensures the correct testing of cable line with sections of underground laying in polymer pipes. To learn more. |

|

|

|

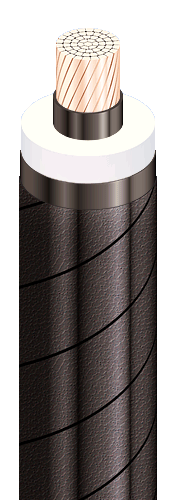

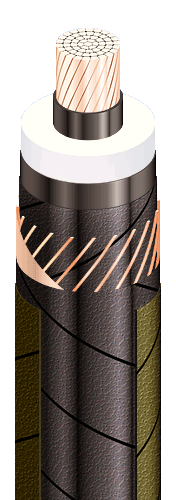

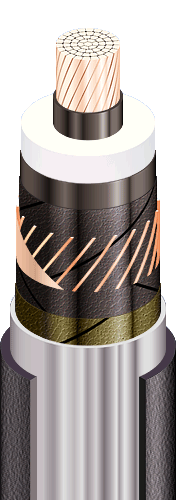

It is possible to manufacture cables with an integrated fiber-optic module.

Order entry example: |

| ÏâÅÑÏó-132 1x800/95 (ÎÌ) ÒÓ Ó 31.3-00214534-060:2011 |

| In conjunction with the DTS system, the integrated fiber-optic module can act as a distributed cable line temperature sensor. To learn more. |

|

|

|

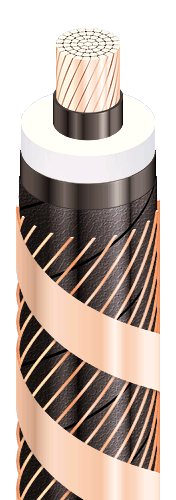

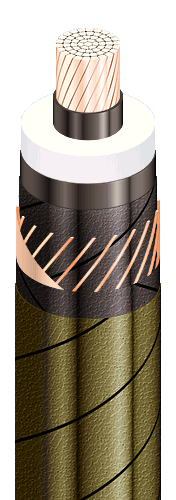

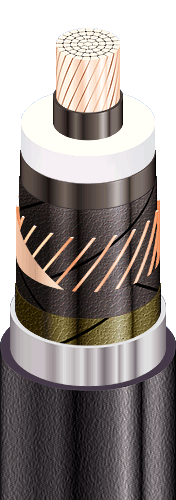

It is possible to manufacture cable with sealed conductor.

Order entry example: |

| ÏâÅÑÏó-132 1x800/95 (ã) ÒÓ Ó 31.3-00214534-060:2011 |

|

|

|